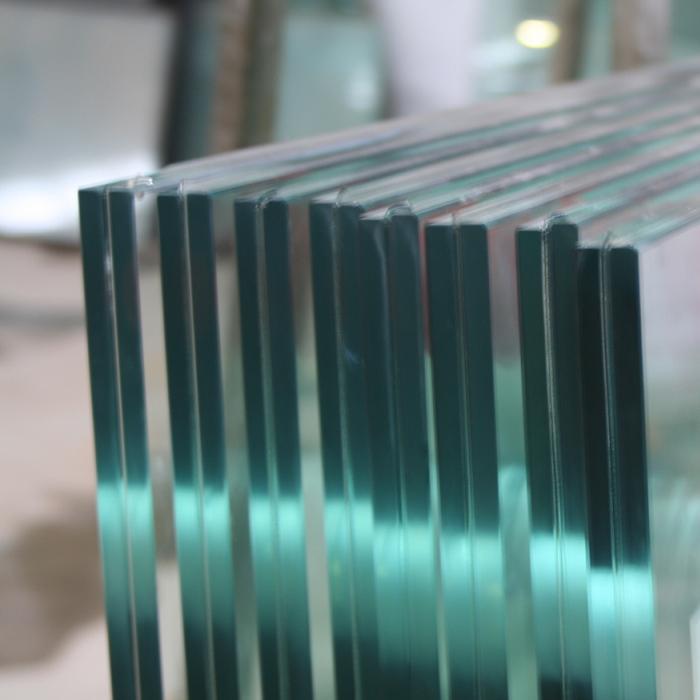

Annealed glass is glass produced without internal stresses imparted by heat treatment, i.e., rapid cooling, or by toughening or heat strengthening. Glass becomes annealed if it is heated above a transition point then allowed to cool slowly, without being quenched. Glass is treated with heat in order to change its properties by the annealing process. Annealed glass is the most common glass used in windows and glass shelves. It is also known as a standard sheet of float glass.The glass, formerly annealed on shelves in a melting furnace. The shaped glass is annealed to relieve stresses caused by manipulation, then is slowly cooled.

Glass which has not been annealed is liable to crack or shatter when subjected to a relatively small temperature change or mechanical shock. Annealing glass is critical to its durability. If glass is not annealed, it will retain many of the thermal stresses caused by quenching and significantly decrease the overall strength of the glass.

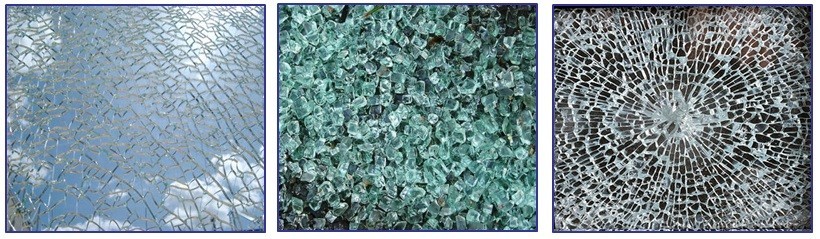

Annealed glass breaks into large, jagged shards that can cause serious injury, thus considered a hazard in architectural applications.

Care should be taken when choosing locations to install annealed glass.

Factors that influence annealing glass breakages

Glass breaks when it is under stresses that it cannot withstand. Each type of glass has different breakage characteristics. In the case of annealing glass, when broken it splinters into sharp fragments, which represent a hazardous situation. Annealing glass may break for many different reasons. We will be focusing on the most common ones.

1. Thermal breakage

Generally, thermal stresses on glass occur as a result of exposure to sunlight and interior heating. When glass is exposed to high temperatures, it absorbs heat and expands. At the same time, its edges remain cooler, creating a differential between the two surface areas of the pane. These expansion differences cause stress and consequently thermal breakage.

2. Different loads

Glass is subjected to different types of environmental and human loads, which can cause the malfunctioning or breakage of glazed surfaces. Since each load has a specific impact on glass, and different calculation formulas, it is important to understand each of these phenomena in order to determine the appropriate glass thickness.

3. Poor glazing

Poor and improper glazing may also lead to glass failure and breakage. Correct handling and glazing of the glass is essential to avoid edge damage and minimize the risks of fractures due to thermal and mechanical stresses.

4. Impacts

Glass can break as a result of several types of impact, which can be categorized as accidental or deliberate . As normal annealed glass is relatively fragile in comparison to tempered glass, a strong impact almost always causes glass breakage.

Bear Glass assure you annealed glass without any manufacturing defect. So eliminating one of the cause of breakage and guarantee a longer life.

CALL OUR EXPERTS AT 718-832-3604 TO DISCUSS YOUR REQUIREMENTS.WHETHER IT’S PURCHASING NEW MACHINERY TO PROVIDE NEW SERVICES OR BRINGING IN DIFFERENT LINES OF GLASS, WE DO IT. WE STRIVE TO KEEP OUR CUSTOMERS SATISFIED, AND ARE ALWAYS LOOKING TO MAKE NEW ONES. WE ENJOY WORKING ONE ON ONE WITH PEOPLE IN THEIR PROJECTS.

1 Response

Misconceptions and Facts: Lies and Truth About the Business of Modeling

The logic of the marketplace today makes your scoop changea